Waterproof Materials (Seal Materials)

Summary of uses

KUNISEAL is a waterproof material that takes advantage of the properties of bentonite. (For more details, refer to "What is bentonite?".) Bentonite is inorganic clay, and continues to produce an excellent waterproof effect semipermanently without degrading.

In placing additional concrete in building or civil engineering works, fine cracks develop due to the cure shrinkage of concrete. Especially, in an underground area, water infiltration from these cracks cannot be avoided. It is KUNISEAL that shuts out such water.

Conventionally, PVC or rubber water stops and waterproof materials have been often used, but KUNISEAL, unique plasticized bentonite, has significantly improved workability, waterproof performance, and durability. KUNISEAL does not require technical skills, and is easy to install, greatly contributing to shorter construction periods and cost reductions.

Bentonite-based waterproof material that stops water infiltration

KUNISEAL(C-31)

Horizontal concrete joint

KUNISEAL(AB-2505)

For pipe circumference

KUNISHEET

Waterproofing an underground outer wall

Since KUNISEAL C-31 was launched, new products have continuously been added to the lineup of the KUNISEAL Series. They have continued advancing as products that expand the market.

Technologies accumulated through the development of KUNISEAL were gathered to develop KUNISHEET, a waterproof sheet. KUNISHEET is a hybrid waterproof sheet made by combining bentonite and special modified asphalt.

It has been attracting attention from various fields as a product that may be able to resolve the difficulty of using waterproof sheets in joints or through holes.

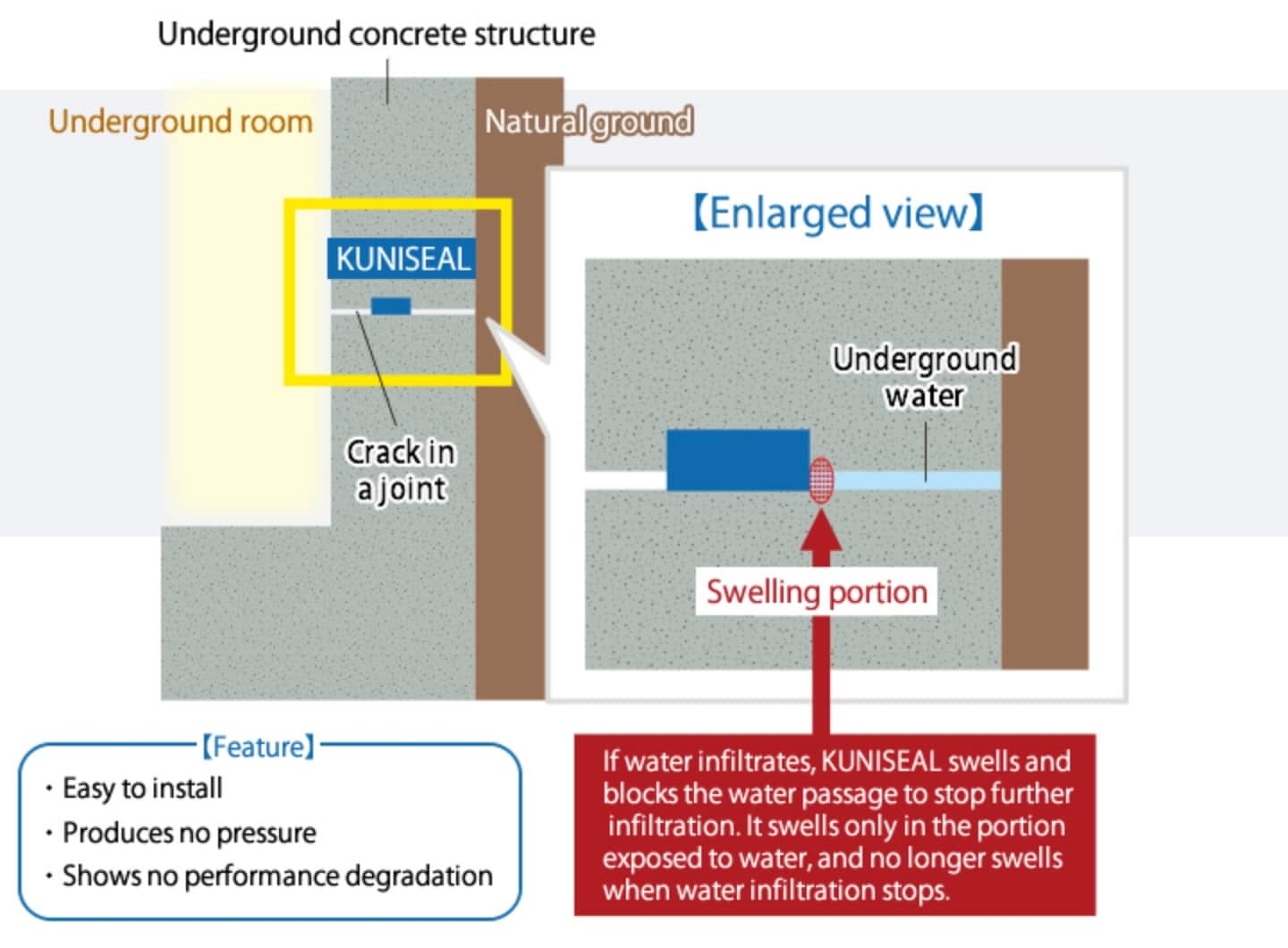

Waterproof mechanism of KUNISEAL

If in contact with infiltrating water, KUNISEAL, whose main component is bentonite, swells and fills fine, uneven cracks in concrete joints. This weather-stripping effect allows it to produce a waterproof effect. The process of swelling following contact with water and drying can be repeated any number of times, which enables the product to retain its waterproof performance semipermanently.

Installation procedure

Dip KUNISEAL in water to dissolve the film

Push KUNISEAL firmly against concrete

Fill a joint with KUNISEAL in such a way as to make a butt joint

- It can be installed easily and reliably, and provides high waterproof performance wherever waterproofing is required.

- It can be installed in uneven surfaces or vertical surfaces without requiring special treatment.

- It can be used anywhere you can reach whether it is between reinforcing bars or a small area.

Product lineup

| Product name | Use | Feature |

|---|---|---|

| KUNISEAL C-31 | Concrete joints | Clay type. Very easy to install and shortens work construction periods. Flexible and free to deform and has the ability to repair itself. |

| KUNISEAL AB-2505 | Concrete joints, Pipe circumference | Tape type made of bentonite and asphalt. The swelling speed can be controlled. Has the ability to repair itself. Has molding stability. |

| KUNISEAL AB-2025Y | Secondary products of concrete | Same as above |

| KUNISEAL AB-H | For H-shaped steel | Same as above |

| KUNISEAL BOND | Adhesive for KUNISEAL AB | Water-based acrylic resin adhesive |

| KUNISEAL EXTERNAL BT | Installation external to concrete joints | Can be nailed and shortens work construction periods. The biodegradable film can be easily installed. |

| KUNISEPA | For separators | The self-fusing product can be cut first and then installed later. |

| KUNISEALPATE XL | Gun type for repair use | Fluid waterproof material for repairing areas of indefinite shape |

| KUNISHEET | Waterproof sheet for outer walls | Has the ability to repair itself and suitable for prior installation in underground waterproofing works. |

| KUNISLEEVE TP | Spiral pipes, etc. | Waterproof material of the new type made of bentonite and butyl rubber |

| KUNISTOPPER PH | Waterproof material for scaffolds | Waterproof material for scaffolds that just needs to be put in place |

FAQ

Are any problems caused by KUNISEAL C-31 swelling before secondary concrete placement?

Be careful not to allow KUNISEAL C-31 to become wet before construction work. If there is a possibility that it will swell due to rain or for another reason after construction work, cover it with a sheet, or provide a drainage ditch in the form, or take another protective measure. The photo shown below is a cross section of swelled KUNISEAL C-31. In this case, KUNISEAL C-31 is acceptable because there is a dark gray non-swelled portion inside the white swelled portion. In addition, the swelled portion does not affect performance because the bentonite repeatedly swells.

State of swelling

Can nails be driven into KUNISEAL. I am concerned about the possibility that nailing will cause air gaps.

Nails can be driven into KUNISEAL. In addition, KUNISEAL can mend the air gaps expected to form by nailing with its flexibility and self-sealability.

Does KUNISEAL swell with chemicals, oils, etc.?

KUNISEAL becomes less likely to show a swelling reaction against strong acids, strong alkalis, and organic solvents.

Does repeated swelling and drying affect performance?

Repeated swelling and drying does not cause the swelling property to change or affect the water sealing performance of KUNISEAL itself.

Won’t concrete develop cracks if KUNISEAL C-31 swells after construction work?

In addition, won’t sealing material be squeezed out?

When KUNISEAL C-31 swells inside concrete, it does not produce a strong swelling pressure. Thus, you do not need to worry about cracks or sealing material being squeezed out. Secure a thickness of cover concreate of 30 mm.

Please tell me how to store KUNISEAL, and its use-by period.

Store it in a cool, dark place, and keep it away from water. Since bentonite, which is the main ingredient, is inorganic clay, performance basically does not deteriorate.