Boring

Summary of uses

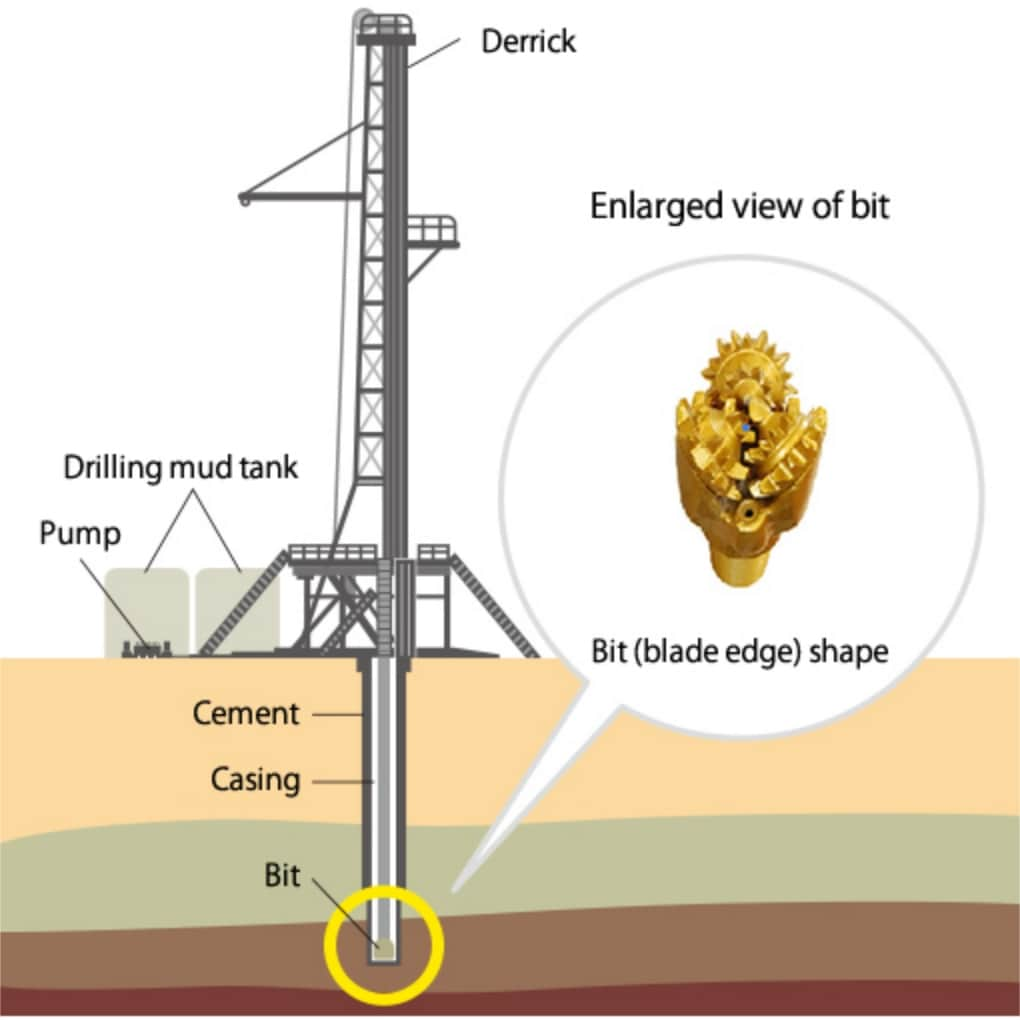

Boring (well drilling) has been conducted for a long time not only to develop underground resources such as petroleum, natural gases, hot springs, and geothermal energy for power generation but also to conduct geological surveys and build a water well. Bentonite has been used previously for drilling mud in boring. In boring a hole that is as deep as 10,000 meters below the ground, the properties of drilling mud is one of the most important elements in the construction.

Drilling mud may be water based or oil based. Generally, bentonite combined with water is used as the basic material, and is further combined with conditioning agents as needed to stabilize the properties.

Geothermal power generation

Platform for offshore oil and natural gas development

Boring for a geological survey

Roles and functions

In the boring field, bentonite-based drilling mud is expected to play the following roles and functions:

- Clean the bottom hole and bit by removing drill cuttings and carry them to the ground.

- Keep drilling mud circulating to cool the core bit at the tip, which burrows through the geological layer with its hard blade and produces frictional heat, and prevent the pipe from wearing due to contact between the casing and the boring rod by taking advantage of the lubricating property of the clay.

- Prevent underground fluids such as petroleum, gases, and water in the geological layer from spouting out.

- Form a thin, robust, and impermeable mud wall in the borehole to prevent the borehole wall from collapsing. (Forming a mud wall of bentonite in the borehole can prevent major collapse, but too thick a wall may cause the boring rod to stick to it and make it no longer possible to continue boring.)

- Retain drill cuttings and additives and prevent them from separating when circulation of the drilling mud is temporarily stopped for extension of the boring rod or another reason. If slime in the drilling mud on the way back to the ground is settled, the boring rod is buried as with the case of borehole wall collapse. The clay is expected to control the viscosity of the drilling mud and help stop slime from falling.

- The general conditions of the tip of the bit and the geological layer deep under the ground can be grasped by analyzing the drilling mud returned to the ground. Direct data can also be obtained from collected drill cuttings.

Overall view of boring

Overall view of boring

Product lineup

| Product name | Petroleum | Natural gas | Geothermal heat | Hot spring | Water well | Geological survey |

|---|---|---|---|---|---|---|

| KUNIGEL GT | ○ | ○ | ○ | |||

| KUNIGEL V1 | ○ | ○ | ○ | ○ | ○ | ○ |

| KUNIGEL VO | ○ | ○ | ○ | ○ | ○ | ○ |

| KUNIGEL GS | ○ | ○ | ○ | |||

| KUNIFORCE PX | ○ | ○ | ○ |

KUNIGEL GT is high-performance bentonite that satisfies the specifications of the American Petroleum Institute (API).

KUNIGEL GT and KUNIGEL V1 are highly heat-resistant bentonite suitable for use in boring for petroleum, geothermal heat, and hot spring development. We provide many other types of bentonite suitable for use in boring.

FAQ

How do you select KUNIGEL GS or KUNIGEL V1 depending on the boring method?

KUNIGEL GS is a product with a low concentration and excellent viscosity development, and it is suitable for geological surveys and water well drilling because its gel viscosity helps transport excavated earth and sand in an efficient manner while stabilizing borehole walls.

KUNIGEL V1 is a product applicable to all drilling mud. It is also heat-resistant, highly compatible with dispersants, and suitable for petroleum, geothermal, and hot spring boring.