Contracted Agrochemical Processing

Summary of uses

We are engaged in contracted manufacture of formulations in the agrochemical industry.

Bentonite is used as a carrier (expander) in agrochemical formulations, and we, as a bentonite manufacturer, had supplied this clay as a raw material for agrochemicals.

Then, we focused on contracted manufacturing of granular agrochemicals and other agrochemical formulations, and are now engaged in contracted manufacture of agrochemicals for agrochemical producers.

There are various forms of agrochemicals such as powder, granular, and liquid forms. Granular formulations, which we mainly deal in, are easy to handle and safe for farmers, and thus have been used as a common agrochemical for a long time.

Recently, the lack and aging of farmers have been a serious problem in Japan, and agrochemicals with various functions for manpower and labor saving have been developed.

Such development requires increasingly complicated manufacturing methods, and the current needs cannot be satisfied without adequate knowledge and technologies related to those manufacturing methods.

KUNIMINE INDUSTRIES provides top-level technologies based on granulation technologies accumulated for many years and by making active use of diversifying formulation technologies.

Agrochemical manufacturing factories

Onahama Factory

This factory specializes in contracted manufacture of agrochemical formulations.

It manufactures and packages herbicides, pesticides, germicides, plant growth regulators, and agrochemical bases.

It can respond flexibly to various needs related to granular formulations.

Koriyama Factory

This factory specializes in contracted manufacture of agrochemical formulations.

It manufactures and packages herbicides only, and is free from risk of cross-contamination with pesticides, germicides, etc.

* Cross-contamination: Refers to the intermingling of different agrochemical products in a manufacturing process.

Ota Factory

It manufactures and packages agrochemicals other than herbicides (pesticides and germicides).

These are available in laminated aluminum bags in addition to conventional 1 kg and 3 kg kraft bags. The factory also has packaging lines for 10 to 20 kg bags.

Manufacture flow

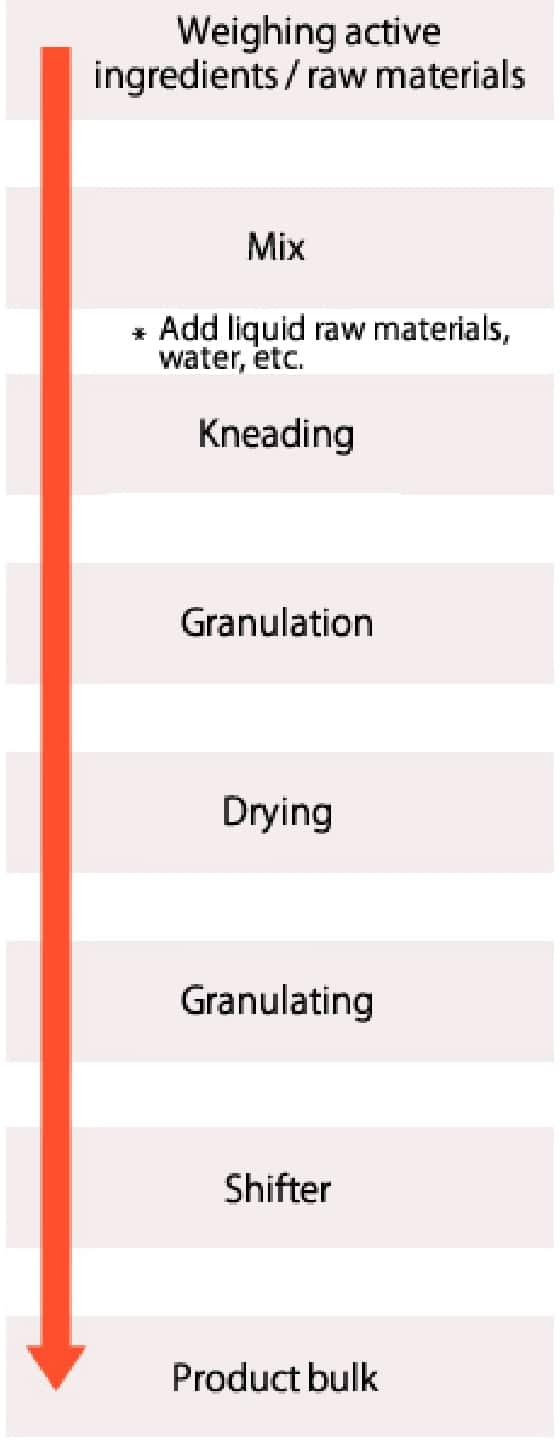

Granulation line

This is ageneral granulation line in the Onahama Factory.The flow can be changed flexibly depending on the manufacturing conditions.

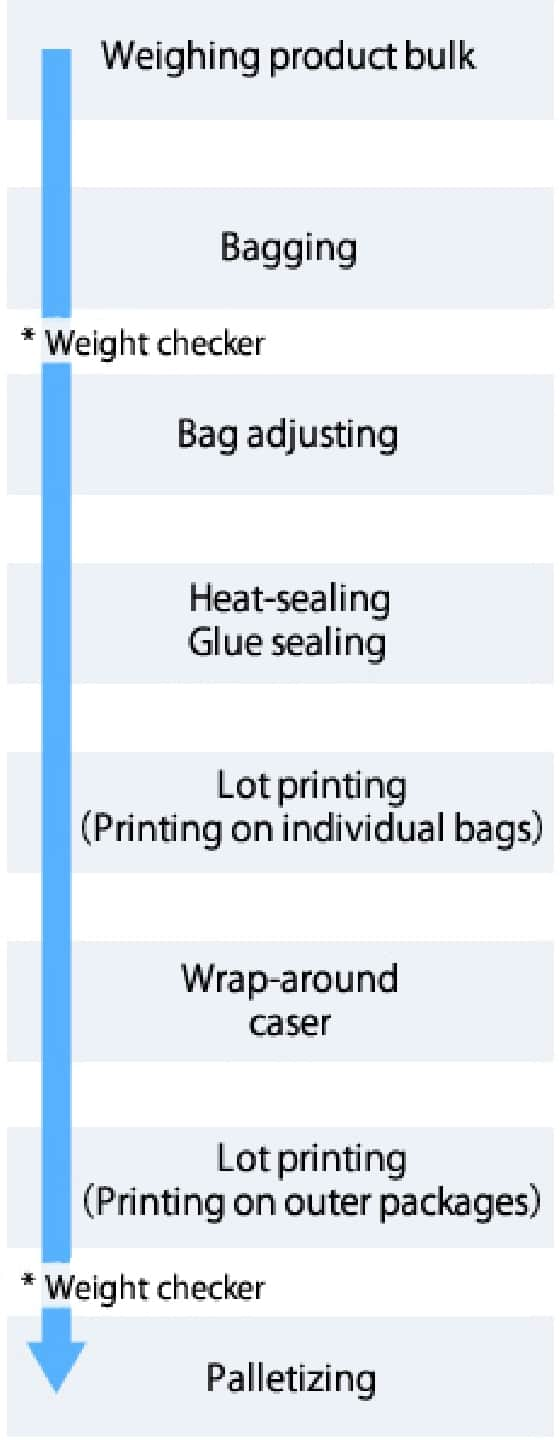

Granular formulation packaging line

This is a packaging line for pesticides and germicides in the Onahama Factory and for herbicides in the Koriyama Factory.

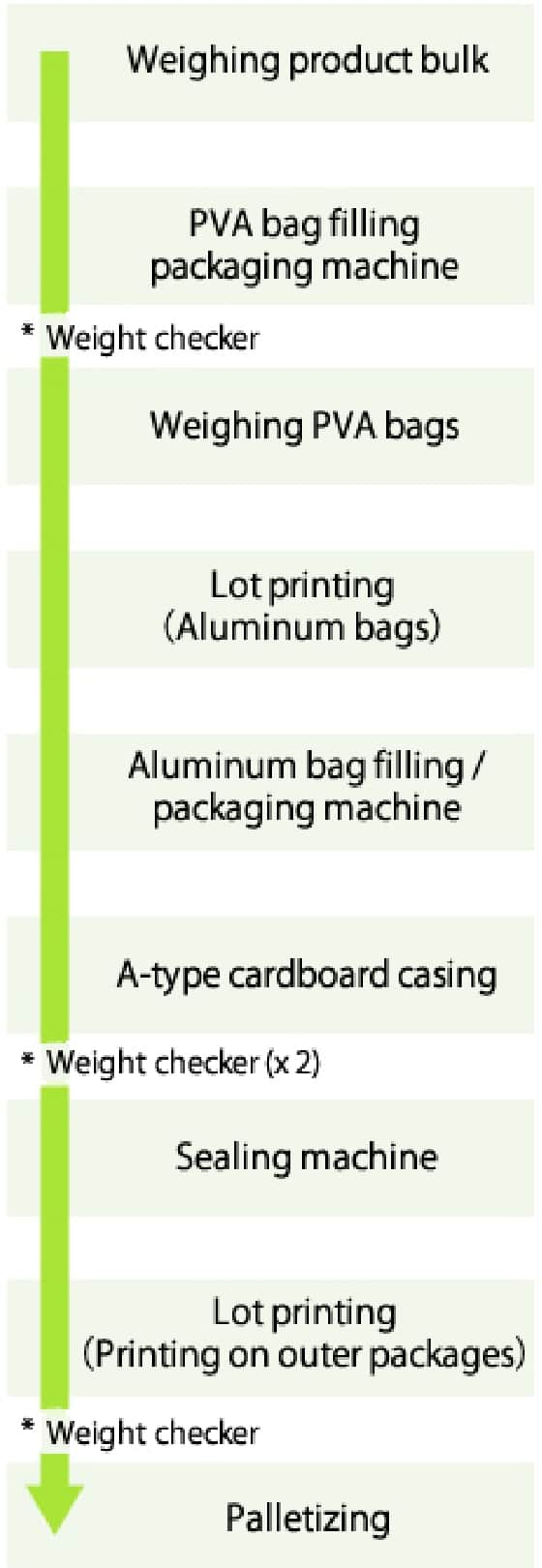

WSB packaging line

This is a WSB packaging line.In this line,packaging bags are made using water-soluble filmes or aluminum films and they are filled in bulk.

Manufacturing lines

List of manufacturing lines

Listed below are manufacturing lines for different agrochemicals (pesticides, germicides, and herbicides) in our agrochemical manufacturing factories.

| Factory | Line name | Pesticides | Germicides | Herbicides |

|---|---|---|---|---|

| Onahama | Adsorption line | ○ | ○ | |

| Granulation line (pesticides and germicides) | ○ | ○ | ||

| Granulation line (herbicides) | ○ | |||

| Coating line | ○ | ○ | ||

| Pre-mixing line (pesticides and germicides) | ○ | ○ | ||

| Pre-mixing line (herbicides) | ○ | |||

| Granular formulation packaging line (pesticides and germicides) | ○ | ○ | ||

| Granular formulation packaging line (herbicides) | ○ | |||

| Packing line | ○ | |||

| Koriyama | Pre-mixing line | ○ | ||

| Granulation line (large-scale) | ○ | |||

| Granulation line (small-scale) | ○ | |||

| Granular formulation packaging line | ○ | |||

| Large packaging line | ○ | |||

| Packing line | ○ | |||

| Ota | Adsorption / coating line | ○ | ||

| Granular formulation packaging line | ○ | |||

| Large packaging line | ○ |

Mixer

High-speed mixer

This machine mixes raw materials and active ingredients homogeneously.

We have mixers that can mix materials homogeneously in only a few minutes and ribbon mixers that can mix large amounts of raw materials at a time.

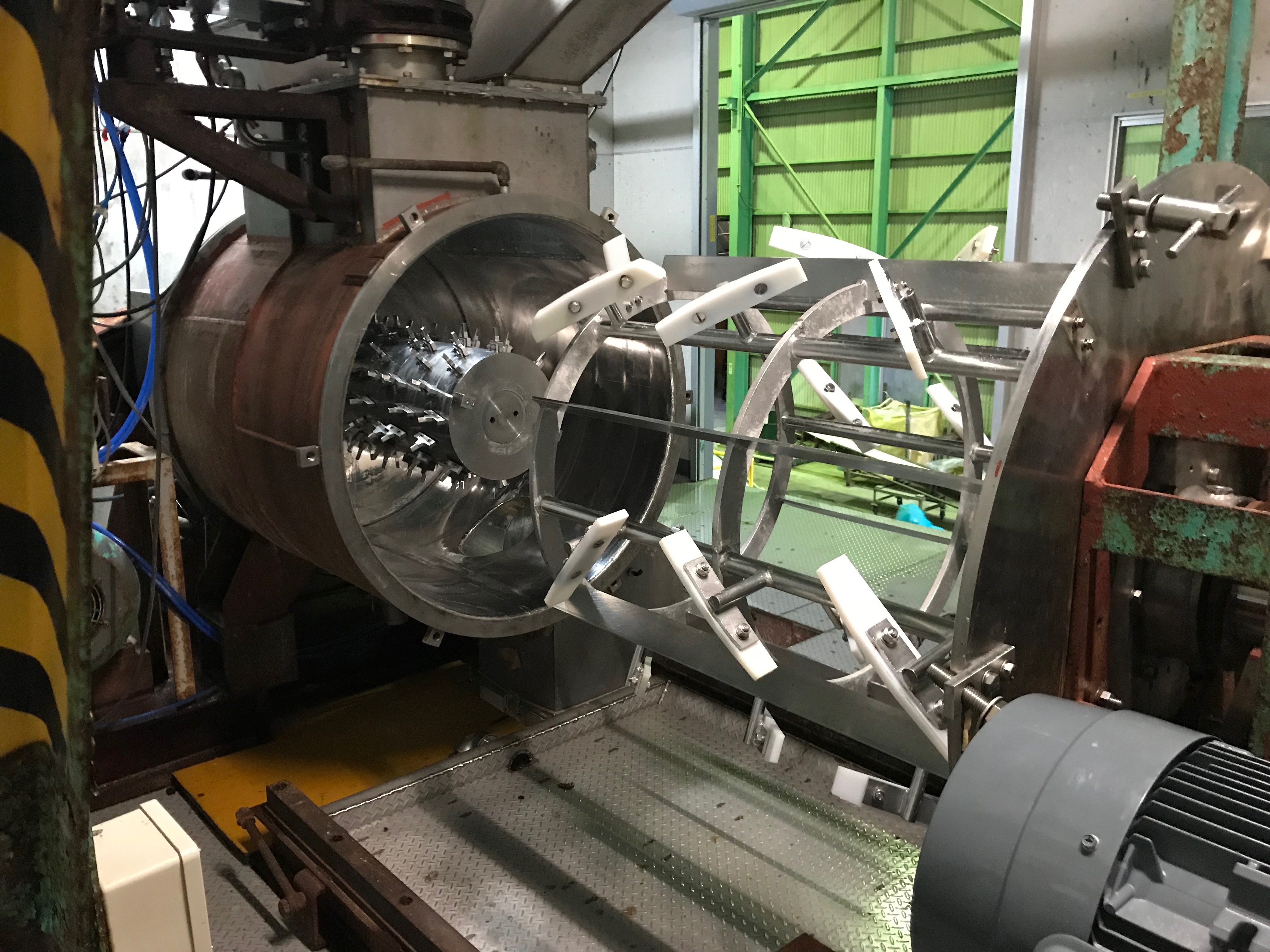

Granulating machines

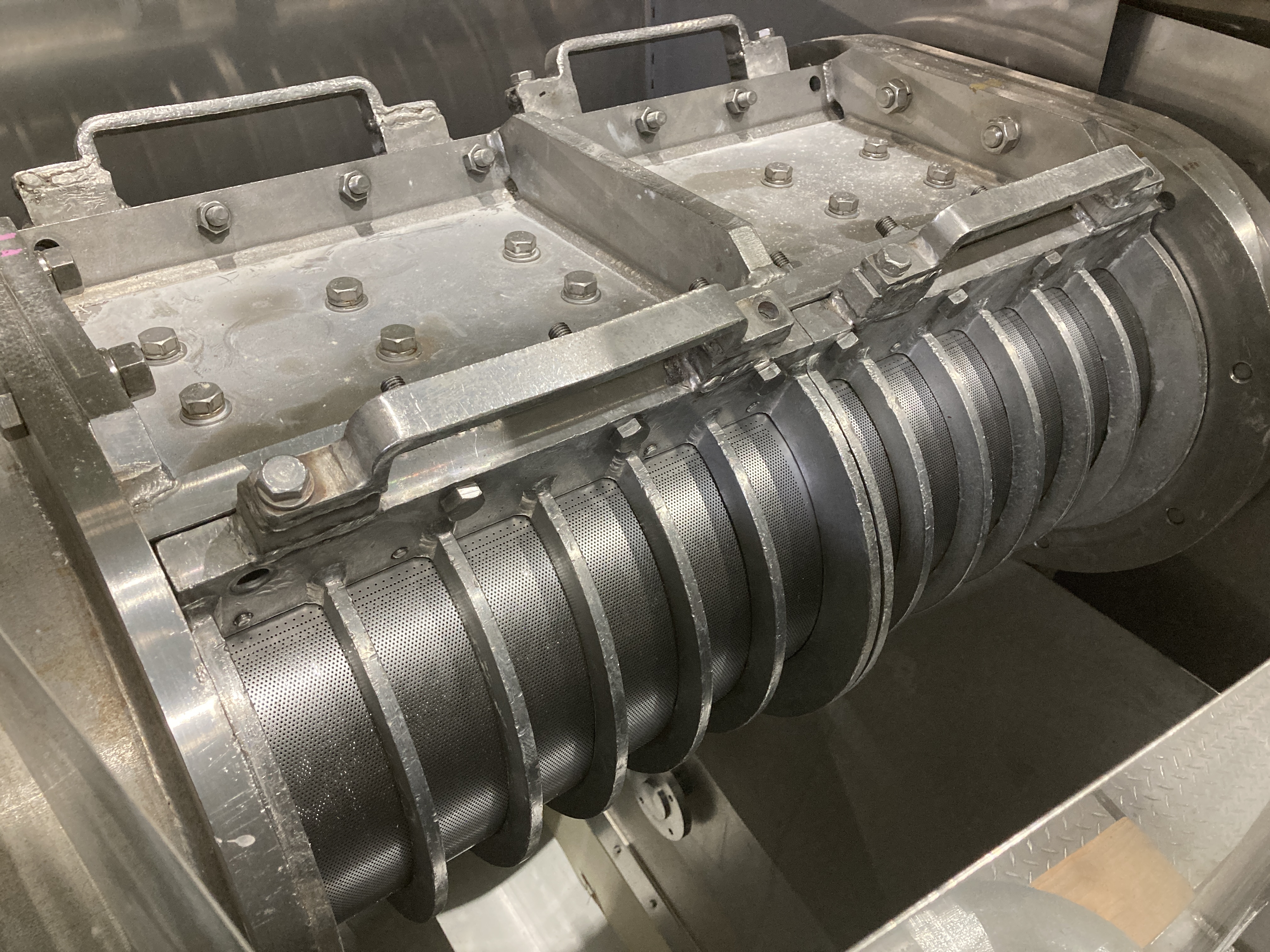

Lateral extrusion-type granulating machine

Basket-type granulating machine

The screw impeller in the granulating machine extrudes a mixture through the screen, producing granules of the screen size.

In the Onahama Factory and Koriyama Factory, lateral extrusion-type granulating machines and basket-type granulating machines, respectively, are mainly used.

Commitment to quality

Engaged in contracted manufacture of agrochemical formulations for a large number of agrochemical manufacturers, we handle a wide variety of active ingredients and raw materials.

As a contract agrochemical manufacturer, we are making efforts to control and reduce risks of these chemicals by properly evaluating their potential risks, and are also committed to preventing cross-contamination.

We clean up machines properly before switching from one product to another to ensure that the level of residual components (active ingredients from the previous product) is below a specified level.

FAQ

Can I contract you to undertake the manufacturing of powder and liquid agents?

At present, we do not undertake such contracted manufacturing. At present, we can offer granules and granular hydrators.

Which is better for the contracted manufacturing of herbicides, the Onahama Factory or the Koriyama Factory?

There are differences in batch scale, granulation equipment, etc. between the factories, and we cannot say one is superior to the other. Determining the appropriateness of equipment will lead to stable production, so please consult us first.

Can I contract only granulation (or only packing)?

Yes, you can.

Is it possible for you to perform small-scale test manufacturing to determine appropriate granulation?

We also have a small-scale laboratory machines (mixer, granulator, dryer, etc.) and can perform test manufacturing of granules in weights of several kilograms.