Green Sand for Casting

Summary of uses

Caking effect of bentonite

Casting is the metal processing method of pouring a molten metal into a mold and castings can be obtained by this method. Many castings are used as parts of automobiles, construction machines, agricultural machines, and machine tools.

A mold used for casting is called a casting mold, a material for a casting mold made by using silica sand as the aggregate and bentonite and water as the caking additives and kneading the mixture is called green sand (or casting sand), and making a casting mold from green sand by compression molding is called mold making. A casting mold obtained by this method is called a green sand mold, and the method of casting using a green sand mold is called green sand casting.

While many processing methods have been developed, green sand casting is used widely around the world because of its low running cost, high productivity per unit time, and other characteristics, and it is believed that about 70% of iron castings, which are used mainly as automobile parts, are made by this casting method. Against such a background, caking additives for green sand for casting are the major application of bentonite in the world.

When bentonite combines with water, it shows a plastic property. Green sand before it is formed into a casting mold also has this property. This is because the properties of the clay are transferred to silica sand coated with the clay.

Various types of bentonite

Bentonite mixtures

The requirements to be met by green sand depend on the casting line. In order to meet various requirements, we provide mixtures of different types of bentonite with different properties (such as highly heat-resistant bentonite and burnable bentonite).

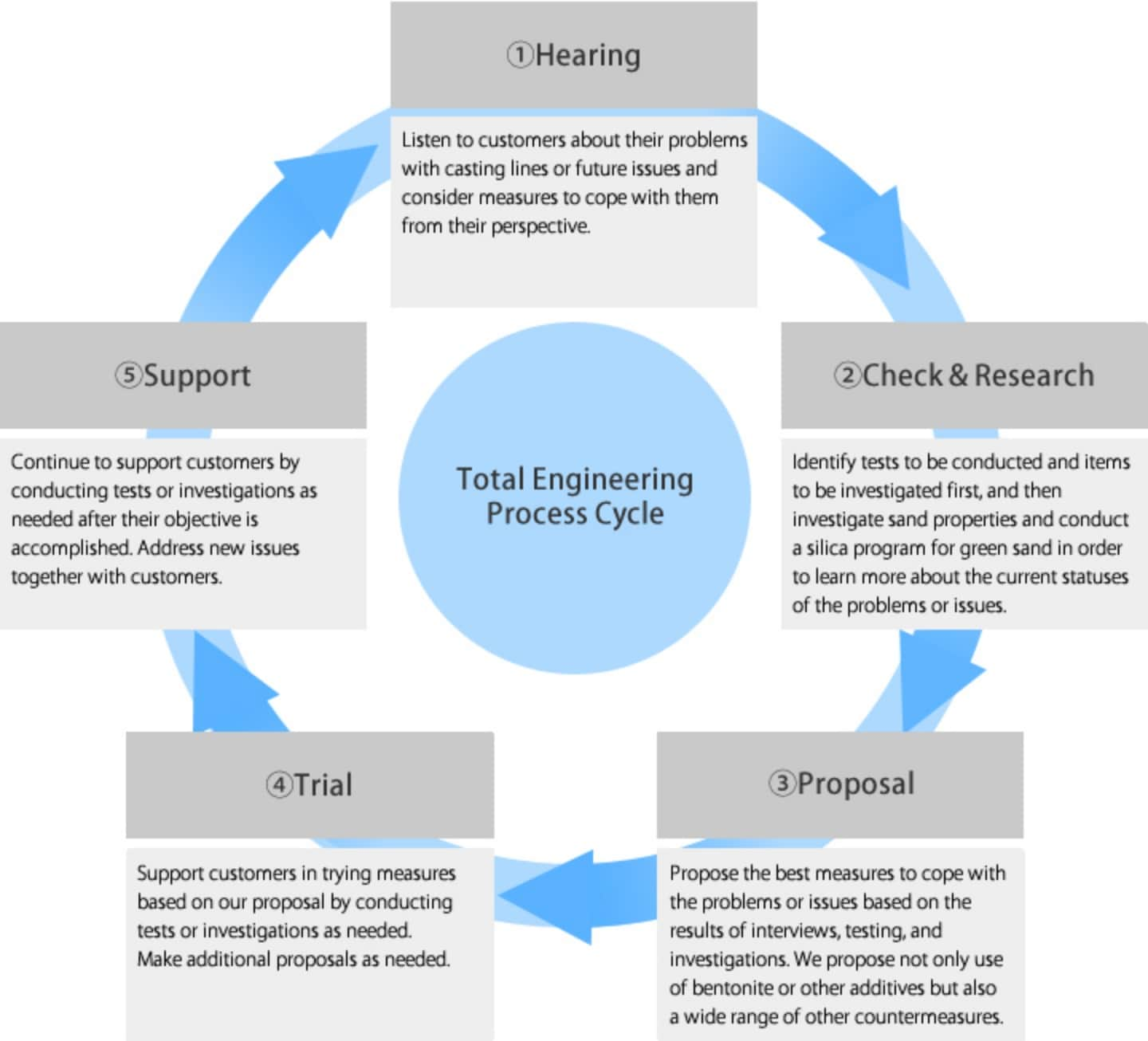

Total engineering

At KUNIMINE, we not only provide bentonite products, but also help customers solve various problems with green sand through our total engineering based on proprietary technologies and know-how accumulated over a long period of time.

Product lineup

Bentonite products

| Product name | Type | Feature |

|---|---|---|

| KUNIGEL VAS | Na | Low water content, Good heat resistance |

| KUNIBOND TY | Na | Ease of sand filling, Good heat resistance |

| NEO-KUNIBOND | Artificial Na type | Fast-acting property, Ease of mold destruction |

Other additives for green sand for casting

- KUNISTACH K (Corn / α-starch) Coal dust, etc.

Bentonite mixtures

- KUNIBOND M Series (KUNIGEL VAS+NEO-KUNIBOND)

- KUNIBOND TY Series (KUNIBOND TY+NEO-KUNIBOND)

We may be able to provide bentonite products already combined with starch or other additives for green sand.

If you have any inquiries, send the inquiry form.

FAQ

Are there any selection examples of mixed bentonite?

For example, if you want to increase the strength of green sand and reduce costs, we recommend an Na type mixed with activated type bentonite.

To use Na type bentonite and increase the strength of green sand, the active clay content needs to be increased, which will result in increased costs and disadvantages, such as the increase of sand clumps. As a solution to these problems, a small amount of mixture of Na type bentonite and activated type bentonite can increase the strength of sand and improve fluidity and collapsibility.

I want to use starch, but I do not have equipment for adding it to green sand.

Do you know a good solution?

We offer bentonite products pre-compounded with starch. By doing so, two materials can be added with an existing bentonite raw material tank and addition equipment, and there is no need to install new equipment. It can also save you the trouble of inventory management.

How do you investigate the characteristics of sand at a production site?

We bring the test equipment necessary for the investigation, or borrow a test machine from the customer. We keep track of the behavior of the characteristics of green sand by conducting tests and collecting data on recovered sand, kneaded (immediately after) sand, and molding (immediately before) sand for a certain period.