Resin Fillers

Summary of uses

montmorillonite crystals

Clay(Smectite) has a sheet-shaped structure that crystal form spreads in two dimensions.

According to this characteristics, high added value to be achieved by dispersing the clay with this structure in organic polymer materials at nano level.

To improve the mechanical properties of resin, gas barrier property, flame retardancy or heat resistance, the clay has been used in various fields.

Expected effects

Additive amount of clay for resin filler is a small percent.

Generally, clay is added by polymerization method as polymerizing monomers in the presence of clay dispersion or melt compounding method as dispersing clay in a polymer directly. These are depending on compatibility of clay and resin, and specifications of using machine, thus optimization is needed. In addition, by using dispersion medium that has an affinity to both the clay and the polymer, relatively easily disperse in the polymer.

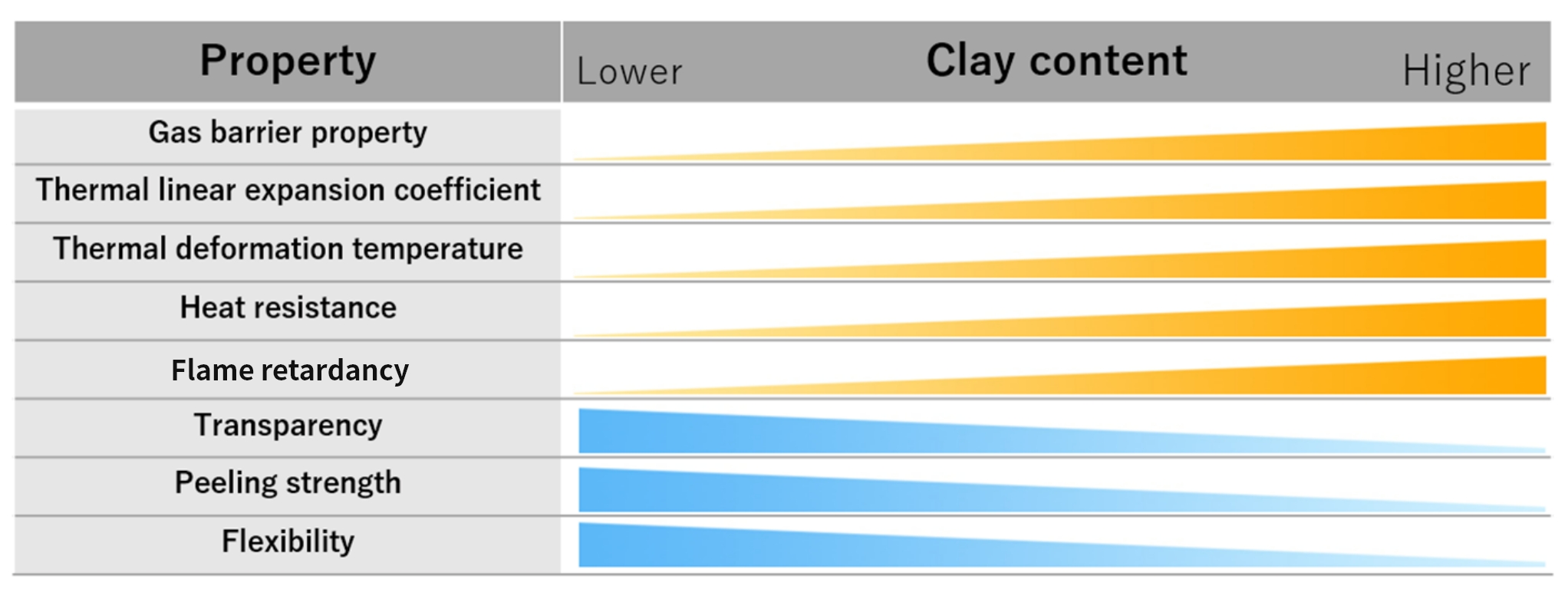

On the other hand, increasing clay contents are further emphasized unique properties of clay such as barrier property, heat resistance and dimension stability are exhibited.

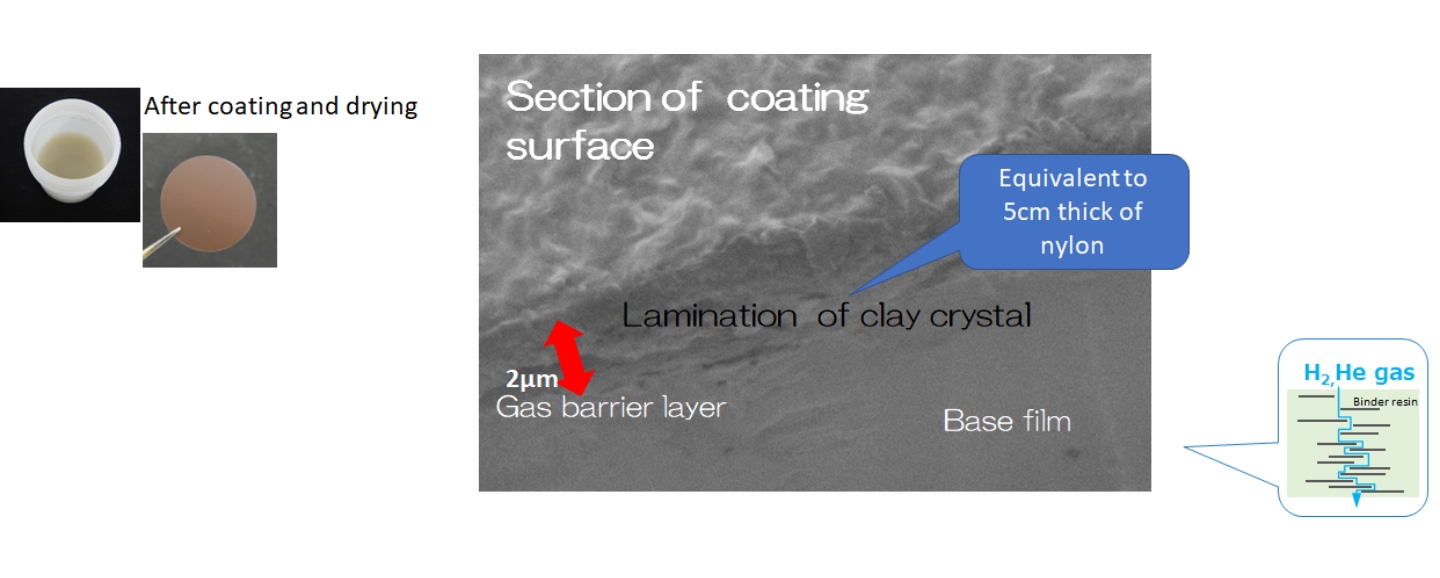

*On gas barrier property, making a solution form that is dispersed a resin and clay then coated, the laminations produce a labyrinth structure which can be improved high gas barrier property.

As the clay contents increase, more clay particles can be layered, so gas barrier property, thermal linear expansion coefficient, heat deformation temperature, flame retardancy and heat resistance are improved during film formation. On the other hand, transparency, peeling strength and flexibility tend to get worse.

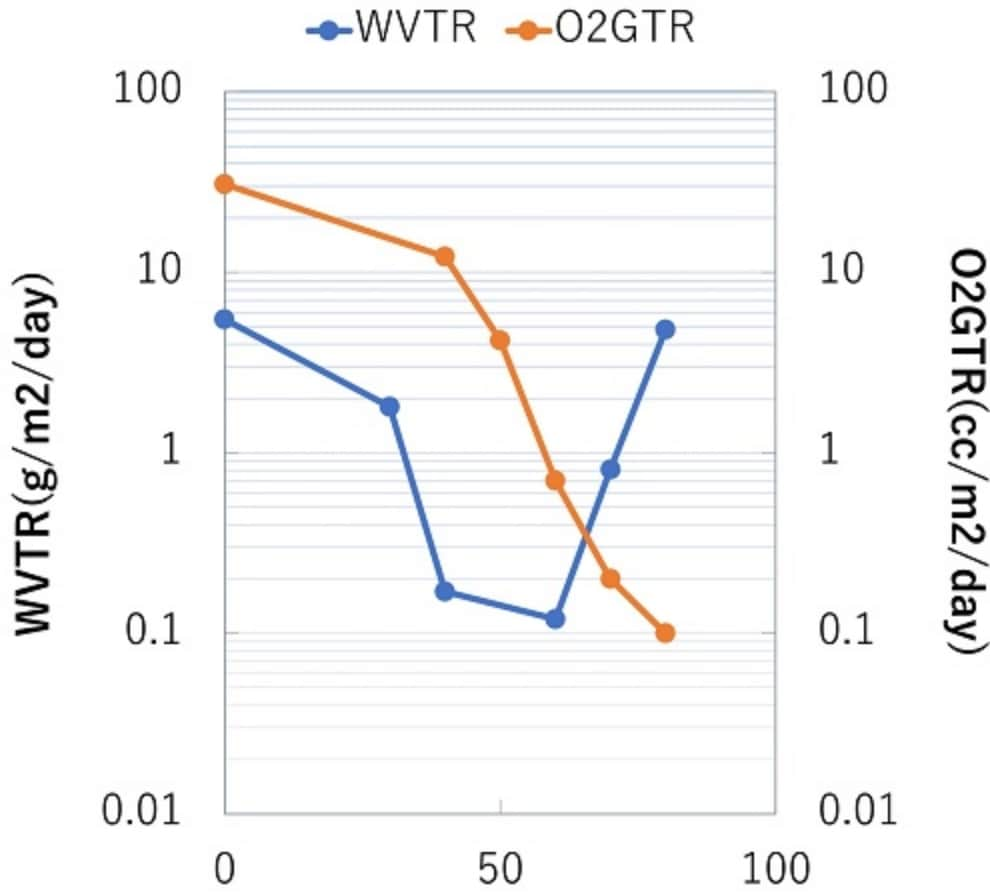

As an example, relationship between the gas barrier property and clay content is shown below.

Gas barrier property depends on resin type (its barrier property, etc.) and clay type (its aspect ratio, etc.), but tends to improve as increased amount added and reaches the maximum value at around 60 to 80wt% of clay content.

In some cases with using clay, 105-fold improvement in gas barrier property compared to resin alone.

| Composition | Kunipia-F + Aqueous emulsion of polyolefin + Crosslinking agent for aqueous resin |

|---|---|

| Dispersion method | Using dispersion mixier and centrifigution defoaming agitator |

| Coating method | Casting on PET material(12.8μm ) then drying |

| Coating thickness | 15μm(Base material + Clay film) |

| WVTR | 40℃, 90%RH (GTR TEC) |

| OTR | 25℃, Dry (OX-TRAN2/21) |

Recommended / Non-recommended

It is said that additive resin is easier disperse if it has polar portions that interact with clay(smectite).

High polar polyamide(nylon), polyurethane, etc. are easy to disperse, in contrast, polyolefin(polyethylene, polypropylene, etc.) as low polarity is difficult to disperse.

Dispersion difficulty of polyester, acrylic, epoxy, etc. is intermediate level between the polyamide and polyolefin in our opinion.

Hydrogen gas barrier

Demands for hydrogen shielding technology of hydrogen energy based society is expected to expand in every aspect of storage, transportation, etc.

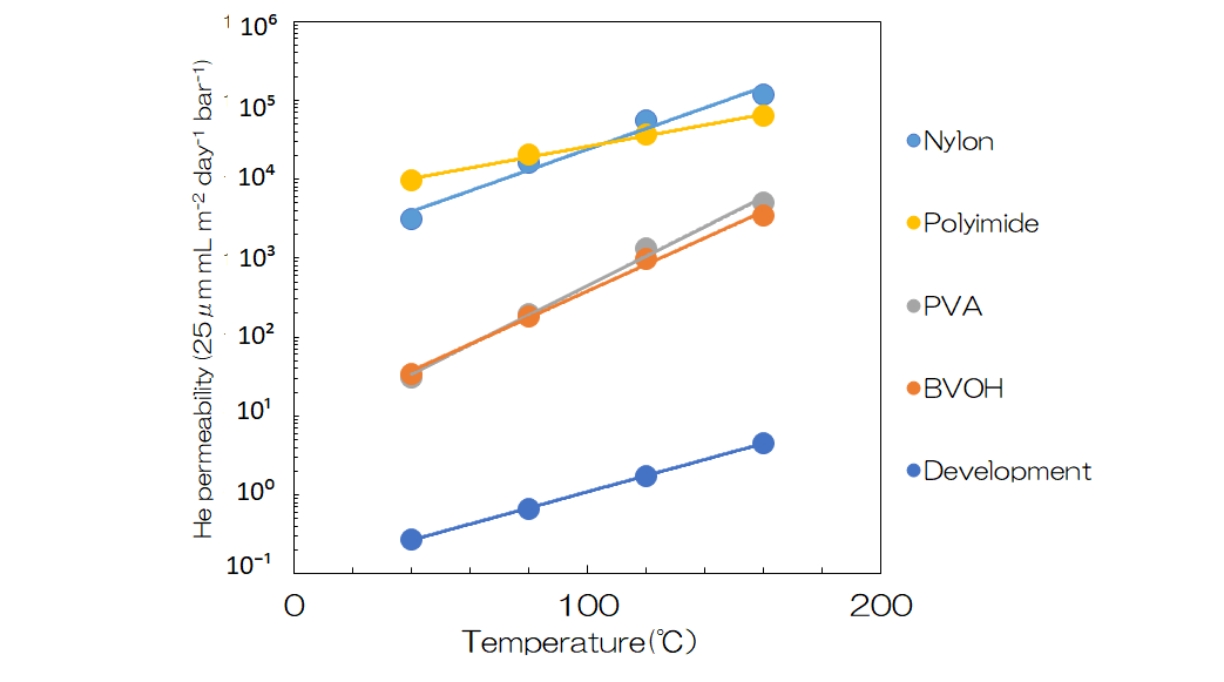

We have developed a coating solution for hydrogen gas barrier property using our hydrophilic clay mineral in the high temperature region. Especially, in the temperature range above 100℃, it shows 25000-fold in gas barrier property of nylon.

Comparison of the dependency of the He gas barrier property on temperature

Precaution for use of organic clay

Organic bentonite and organic synthetic hectorite improve dispersibility in low polarity resins and solvents, but at the same time, contain up to 50wt% and 70vol% of organic components that do not have barrier performance.

Therefore, there are some reports that gas barrier property is impaired adversely by compounding clay mineral.

Product lineup

For industrial applications

| Product name | Category | Suitable primary dispersing medium |

|---|---|---|

| KUNIPIA-F | Refined bentonite | Water |

| KUNIPIA-G | Refined bentonite | Water |

| KUNIPIA-G4 | Refined bentonite | Water |

| SUMECTON-SA | Synthetic saponite | Water |

| SUMECTON-ST | Synthetic stevensite | Water |

| SUMECTON-SWN | Synthetic hectorite | Water |

| SUMECTON-SWF | Synthetic hectorite | Water |

| KUNIVIS-110 | Organic bentonite | Low- to moderate-polarity organic solvent |

| KUNIVIS-127 | Organic bentonite | Low- to moderate-polarity organic solvent |

| SUMECTON-SAN | Organic synthetic hectorite | Low- to moderate-polarity organic solvent |

| SUMECTON-STN | Organic synthetic hectorite | Medium- to high-polarity organic solvent |

| SUMECTON-SEN | Organic synthetic hectorite | High-polarity organic solvent |

For gas barrier applications

| Product name | Form | Design concept |

|---|---|---|

| KUNIPIA-F | Powder | Clay for oxygen gas barriers |

| KUNIPIA-G | Flake | Clay for oxygen gas barriers |

FAQ

I want to mix resin fillers with various resins. Do you have any recommendations?

We have KUNIVIS-110 made of general-purpose grade natural clay and various types of synthetic clay. Please feel free to contact us about them.

How much clay should be added?

It depends on the characteristics, but adding only several percent clay can improve quality. When melt moldability, which is a characteristic of resins, is taken into account, it is about 10%.

On the other hand, in a dispersion system with the existence of a solvent, the concentration can be further increased to about 70%.

I would like to designate an organic modifier for my company. Can you manufacture it?

Before manufacturing it, we can provide a trial product as a contract-developed product. Other types of special treatment can also be offered as needed.