General Waste Disposal Site

Summary of uses

In final disposal sites for general waste, bentonite is used as the clay material of the low-permeable layer in the seepage control work for the bottom of the landfill sites.

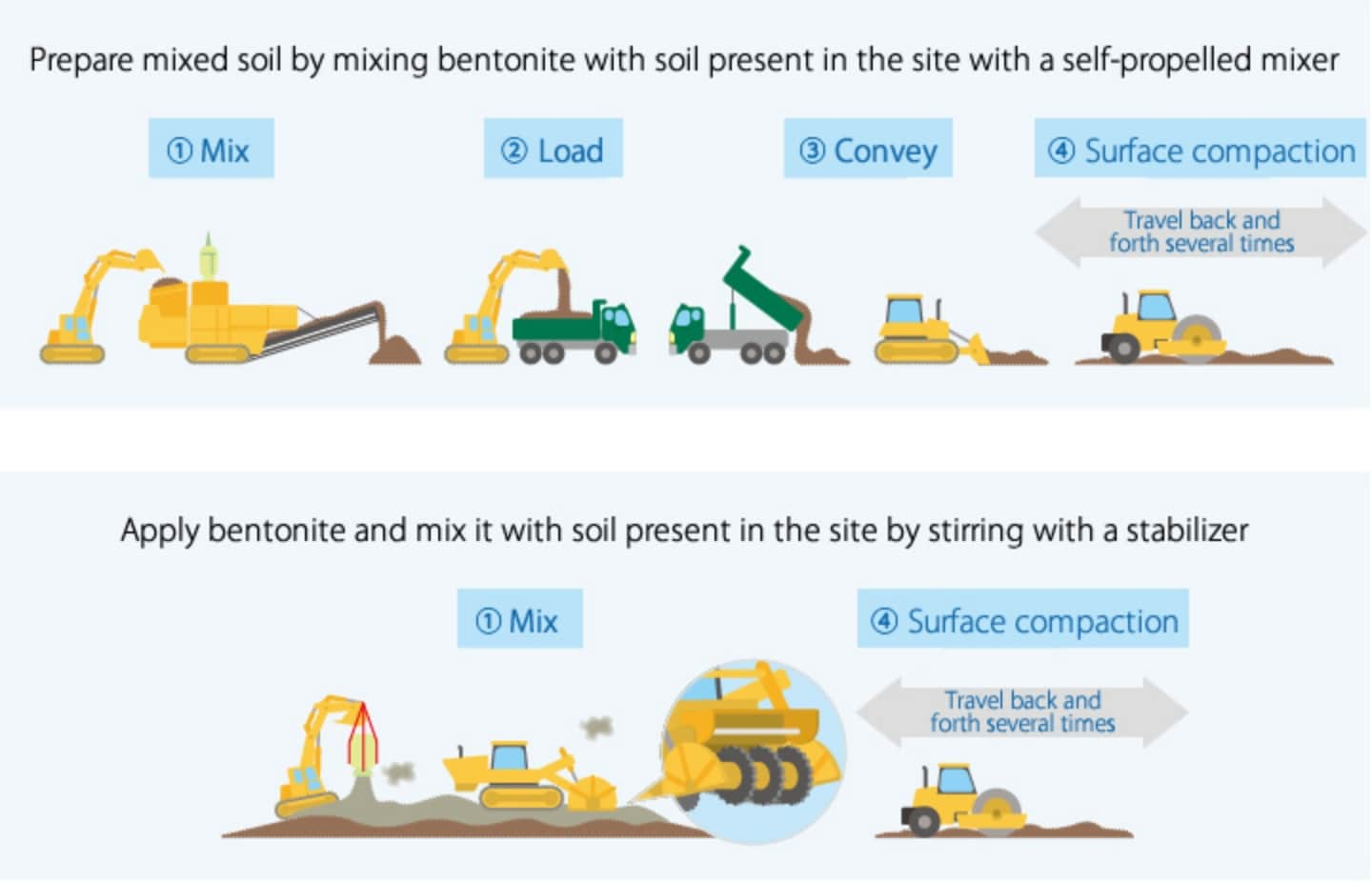

In designing a low-permeable layer, soil present in the site is mixed homogeneously with quality sodium-type bentonite, and the mixed soil is laid on the bottom and slope and compacted by a compaction roller to form an impermeable layer.

Soil mixed with bentonite is prepared in the site. Soil present in the site is combined with bentonite at a given ratio (to have a given water content).

If crushed stone of bentonite obtained by crushing raw ores of bentonite to a given grain size is used as a low-permeable layer, it need not be mixed with soil present in the site, but can be directly laid and compacted by a compaction roller to form an impermeable layer.

Bentonite used in the seepage control work for a waste disposal site

Preparation of soil mixed width Bentonite

Compaction of crushed stone of bentonite by a compaction roller

Measurement of the combination ratio of bentonite

The combination ratio of bentonite to soil present in the site is determined based on the results of laboratory combination tests or on-site test construction before combination.

The combination ratio of bentonite in soil mixed with bentonite in the site can be measured based on the viscosity of the mixed soil and controlled on-site.

Construction examples

Product lineup

| Product name | Use | Feature |

|---|---|---|

| KUNIGEL U | Powdery form | Versatile |

| KUNIGEL V1 | Powdery form | High-grade product |

| KUNICAP TG | Granular form(40 mm or smaller) | Available in a granular form and need not be mixed with soil present in the site. |

FAQ

Please tell me about the advantages of bentonite water sealing layers.

There are several types of water sealing work structures, and a water sealing work method using bentonite water sealing layers is one of them. Since a bentonite water sealing layer is swellable, is highly durable, and has a low permeability coefficient, it ensures a higher fail-safe function against accidents than a water sealing work method using only a

water sealing sheet.

It also leads to the effective use of locally produced soil.

What is the permeability coefficient?

The permeability coefficient indicates how fast water moves, and it is expressed in m/s.

The permeability coefficient required for bentonite water sealing layers at general waste final disposal sites is 10-8

m/s or less.

Please tell me how to determine the amount of bentonite to be compounded.

The amount of bentonite to be used can be calculated using the specified calculation method. The amount of bentonite to be compounded to achieve the designated permeability coefficient is calculated in a permeability test by KUNIMINE INDUSTRIES or an external organization. In addition, the permeability coefficient varies depending on locally produced

soil, the designated base material, and the compaction conditions.

If you need a permeability test, please consult us.

Please tell me how to calculate the amount of bentonite to be used.

For example, when using bentonite-mixed soil containing a 10% outside ratio of bentonite to the dry weight of locally produced soil, assuming that the bulk density of the locally produced soil is 1.2 g/cm3, the water content is 10%, and the bulk density of bentonite is 0.8 g/cm3, add 0.14 m3 of bentonite to 1 m3 of locally produced soil.

For further information, please contact the construction work company.

Please tell me how to store and dispose of bentonite.

Keep bentonite away from water during storage. Furthermore, dispose of bentonite as industrial waste.