Research & Development

Research & development strategies and policies

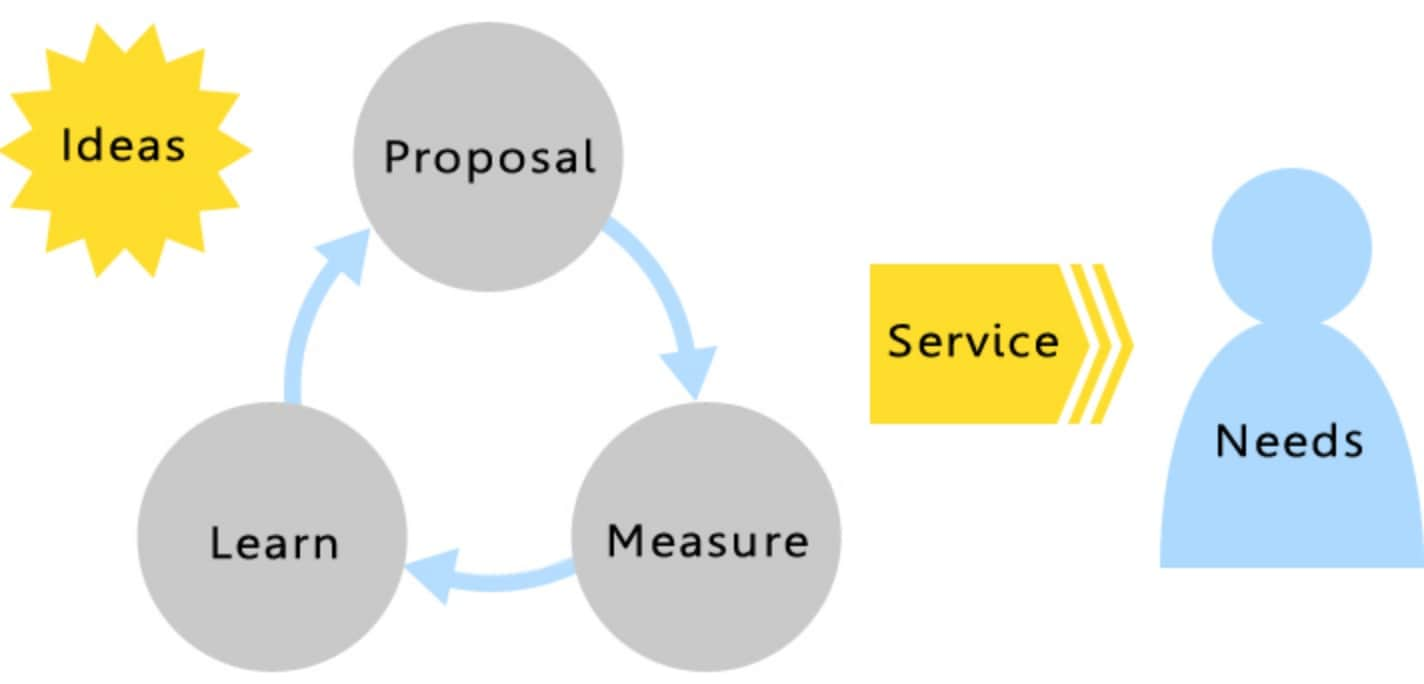

Development policies

Our motto in developing and proposing products is "Put our head together with customers and resolve issues." We bring out the potential of clay considered to have 1,000 uses with our technologies and provide products appropriate for customers' needs.

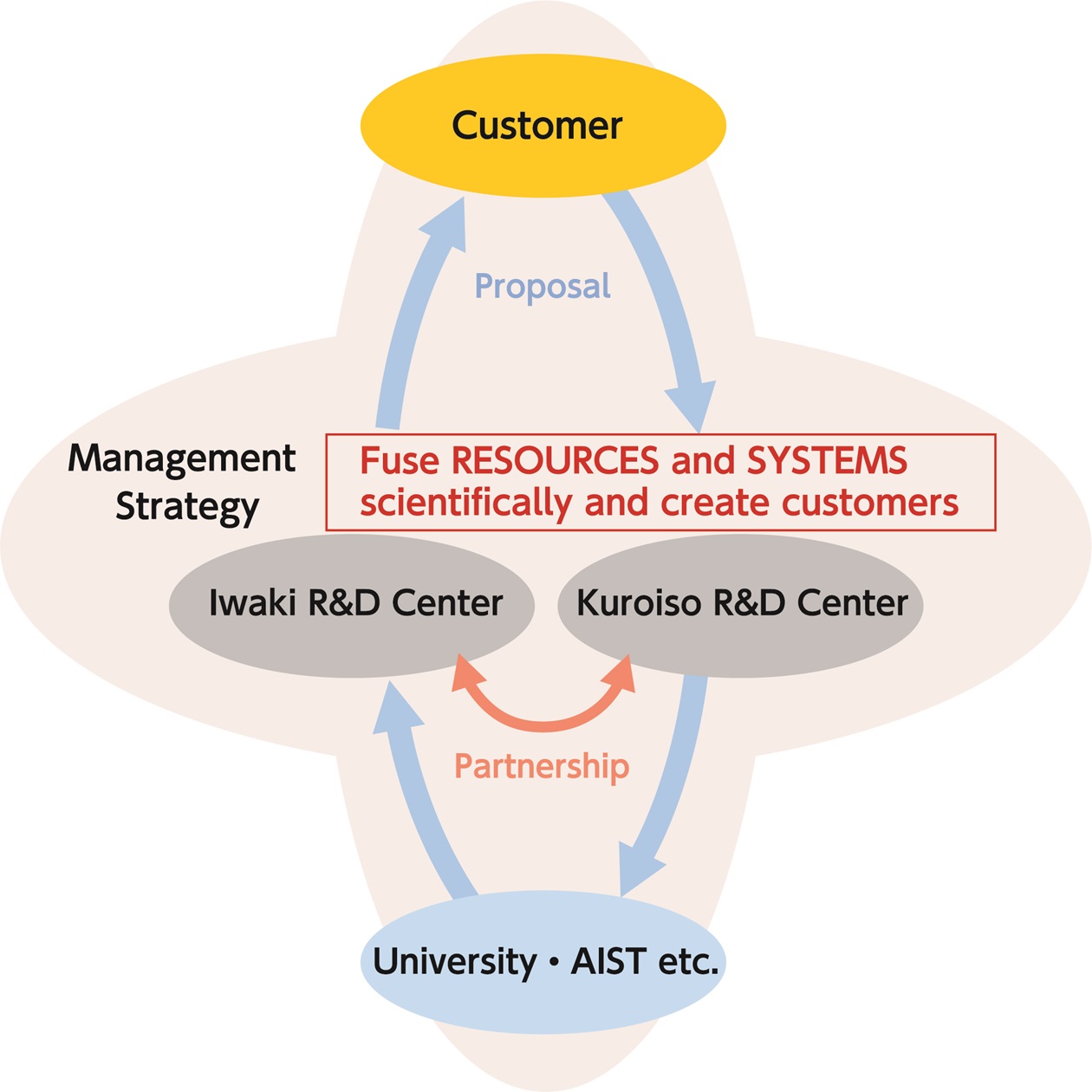

Structure for collaboration

Vertical collaboration in the process of new product development ranging from basic research and applied development to product proposal is realized by conducting joint research with universities and public research institutes, making proposals for and serving customers, and conducting joint research with them as needed. In addition, lateral collaboration between the Iwaki Laboratory engaged in applied development and the Kuroiso Laboratory engaged in analysis and basic research enables prompt development.

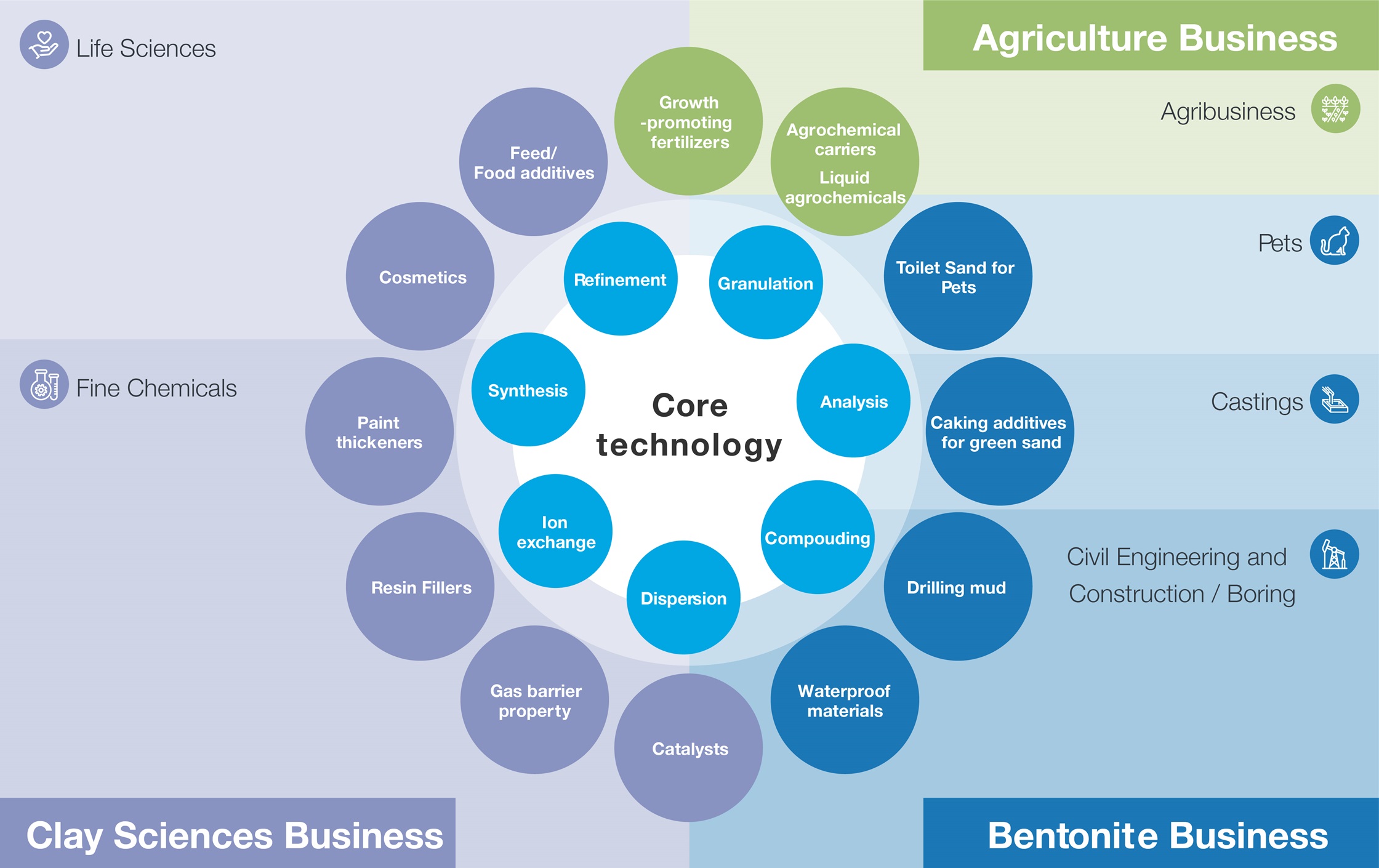

Core technologies

Technology map

Based on application of core technologies that take advantage of the properties of clay, our products are used in various fields. Recently, progress has been made in new applied development combining core and peripheral technologies, and the clay has been used in an increasingly wider range of fields including the functional materials field.

Examples of development in new fields

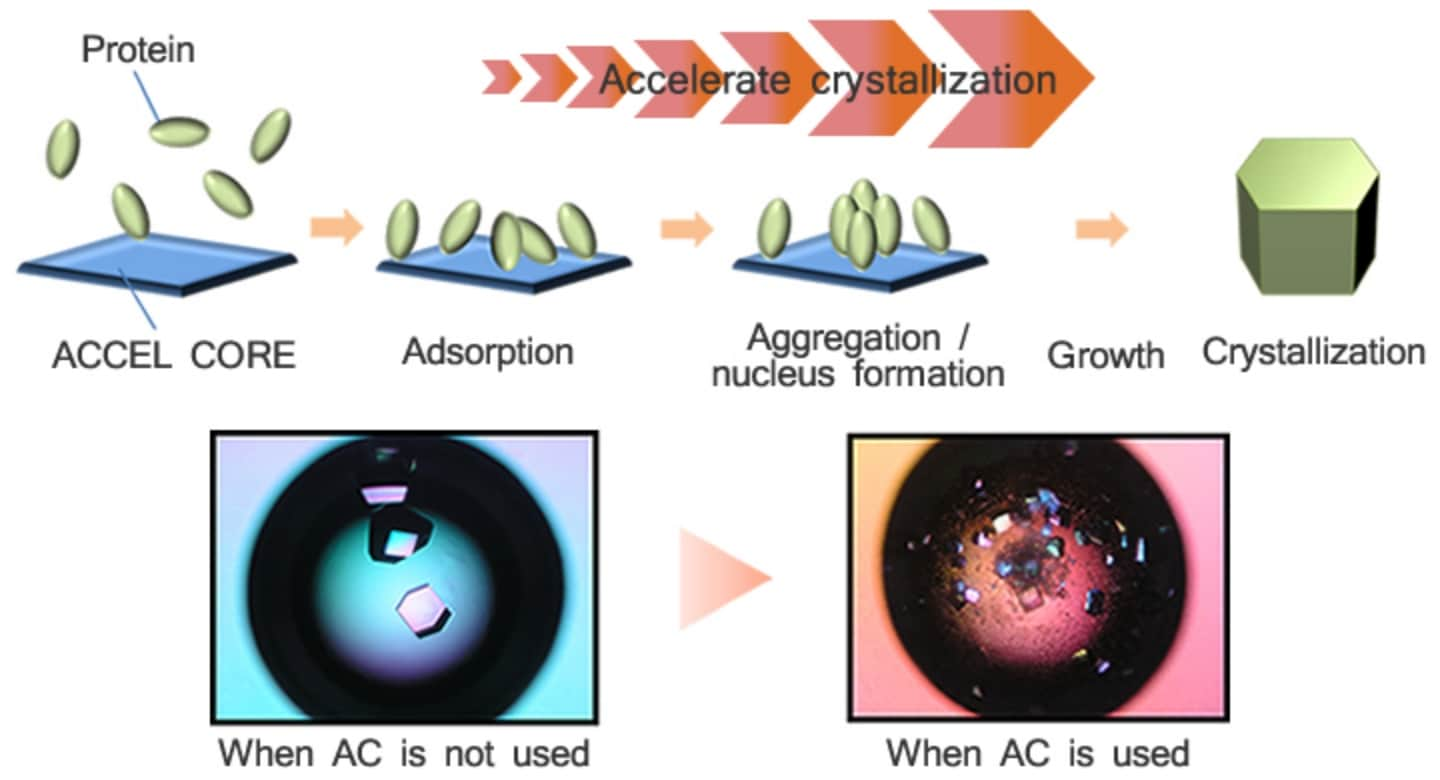

The characteristics of clay minerals are utilized to promote and control protein crystallization.

Clay minerals, which have a high affinity for organic substances, are said to be the origin of life in the primitive earth.

It is known that the surface of clay has catalytic ability and adsorption ability. Currently, it is believed that organic substances are adsorbed to the surface of clay in hydrothermal vents to cause formation, accumulation,

polymerization, and other reactions of biomolecules. Generally, a place where such a reaction takes place is called a magic surface, which may be a key to solving the mystery of the beginning of life.

The development of medicine is supported by the development of testing equipment and new pharmaceuticals. The process

of developing a new pharmaceutical begins with a structural analysis of the target, which requires crystallized

materials. If the target is an unknown protein, it takes an immense amount of time and effort to find the

crystallization conditions.

We came up with the idea that if we can take advantage of the properties of clay minerals, which are said to be the

origin of life, to promote and control the crystallization of proteins, the speed of development of pharmaceuticals can

be increased dramatically.

Research & development

We carried out material development and evaluation tests simultaneously with the cooperation of Tokyo University of Science.

When the origin of life is mentioned, natural clay may come to your mind. We have various kinds of natural clay with globally unique properties. However, because there was a need to design a material itself in order to control the properties as desired or obtain desired properties, we used our own synthetic clay as a material for development this time.

| Protein type | Molecular weight(kDa) | Isoelectric point | Electric charge | Number of days required for crystallization | |

|---|---|---|---|---|---|

| Without AC | With AC | ||||

| Aprotinin | 6.5 | 9.2 | + | 7 | 2 |

| Avidin | 14.3 | 9.7 | + | 5 | 1 |

| Concanavalin A | 25.6 | 6.0 | + | 26 | 13 |

| Lysozyme | 14.3 | 9.3 | + | N.C. | 22 |

| Thaumatin | 22.2 | 8.3 | + | 55 | 25 |

| Trypsin | 23 | 10.1 | + | N.C. | 34 |

| Albumin | 66 | 4.7 | - | N.C. | 14 |

| Catalase | 240 | 5.5 | - | 12 | 5 |

| Gulucose isomerase | 172 | 5.0 | - | N.C. | 2 |

| Proteinase K | 28.9 | 8.3 | - | N.C. | 8 |

| L-Lactate dehydrogenase | 32.8 | 5.9 | - | N.C. | 5 |

| Xylanase | 21 | 9.0 | ± | 8 | 2 |

Reference

Heterogeneous nucleation of protein crystals on fluorinated layered silicate. PLoS ONE. Vol6, Issue7, e22582, July, 2011.

Crystallization of a protein was an unknown territory that we had not entered, and we had to do demonstrations under various conditions and reflect the results of those demonstrations in material development, and faced a lot of difficulties.

However, researchers' strong desires to contribute to the development of new pharmaceuticals and to take on new challenges in the unknown territory enabled us to overcome these difficulties, and finally, a new product, ACCELL CORE, was completed.

Using ACCELL CORE in the process of crystallization makes it possible to crystallize proteins that could not be crystallized previously, and significantly reduces the time required for crystallization.

The potential of ACCELL CORE is still growing.

ACCELL CORE will further grow in the future through customization to suit various needs, such as pharmaceuticals that can selectively promote crystallization of a certain target, or those that work on a wider range of targets.

We will continue to pursue the potential of clay minerals and contribute to society by taking advantage of their unique properties.

Research & development facilities

Kuroiso Laboratory

The Kuroiso Laboratory always accepts requests for contracted evaluation tests and analyses on bentonite.

| Field | Item | Equipment available / used |

|---|---|---|

| Properties of bentonite | Water content | |

| pH | ||

| Conductivity | ||

| Amount of methylene blue adsorption | ||

| Amount of leaching cations | ||

| Cation exchange capacity | ||

| Chemical composition | X-ray fluorescence spectrometer | |

| Mineral identification | Powder X-ray diffractometer | |

| Differential thermal analysis | Differential thermal analysis equipment | |

| Electron-microscopic surface observation | Scanning electron microscope | |

| Electron-microscopic composition analysis | Energy dispersion X-ray analyzer | |

| Particle size distribution (wet / dry) | Laser diffraction particle size analyzer | |

| Full-automatic sonic sieving particle size analyzer (Robot Sifter) |

||

| True specific gravity | Dry automatic densimeter | |

| Specific surface area | Surface area measuring instrument | |

| Ion quantification | Atomic absorption spectrophotometer | |

| Whiteness | Spectrophotometer | |

| Ion quantification | Ion chromatograph | |

| Ion quantification | ζ-potential |

X-ray fluorescence spectrometer

Scanning electron microscope

The laboratory also conducts contracted tests and analyses in special fields related to bentonite on a routine basis.

| Field | Test item | Test details |

|---|---|---|

| Green sand for casting | Green sand test | Compactability |

| Green compression strength | ||

| Surface stability | ||

| Air permeability | ||

| Moisture-condensed layer tensile strength | ||

| Silica program | Total clay | |

| Active clay | ||

| Ignition loss | ||

| Metal content | ||

| Hydrofluoric acid solubles | ||

| Particle size distribution | ||

| Residual ratio of starch | ||

| Civil engineering and building foundations | Viscosity test | B-type viscometer |

| FANN Viscometer | ||

| Rion viscometer | ||

| Soil test | Soil particle density | |

| Water content | ||

| Liquid limit, plastic limit | ||

| Permeability test | ||

| Compaction test | ||

| Pets | Cat litter test | Apparent specific gravity |

| Cat litter solidification test | ||

| Deodorizing power | ||

| Water absorption |

In addition to conducting contracted tests and analyses, the laboratory holds courses for green sand engineers. Over 120 courses have been held, starting 30 years ago.

At a course for green sand engineers ①

At a course for green sand engineers ②

Iwaki Laboratory

The Iwaki Laboratory always accepts requests for various kinds of granulation and contracted development of refined clay or synthetic clay.

| Field | Item | Major equipment available / used |

|---|---|---|

| Cosmetics Paint thickeners |

Lipophilization treatment Silicate mineral synthesis Compounding |

Lipophilization treatment plant |

| Hydrothermal synthesis device | ||

| Vacuum emulsification device | ||

| Batch kneader | ||

| Homo mixer | ||

| Resin Fillers Clay films Catalysts Adsorbents |

Ion exchange Compounding |

Cation exchange equipment |

| Centrifugal mixer | ||

| Wet grinding mill | ||

| Vibrated membrane filtration system | ||

| Granulation Coating |

Extrusion granulation Stirring granulation Fluidized-bed granulation |

Vertical / horizontal extrusion granulator |

| High-speed agitation granulator | ||

| Fluidized-bed granulator |

Pilot facility for ion exchange

Lipophilization treatment plant

Element technologies

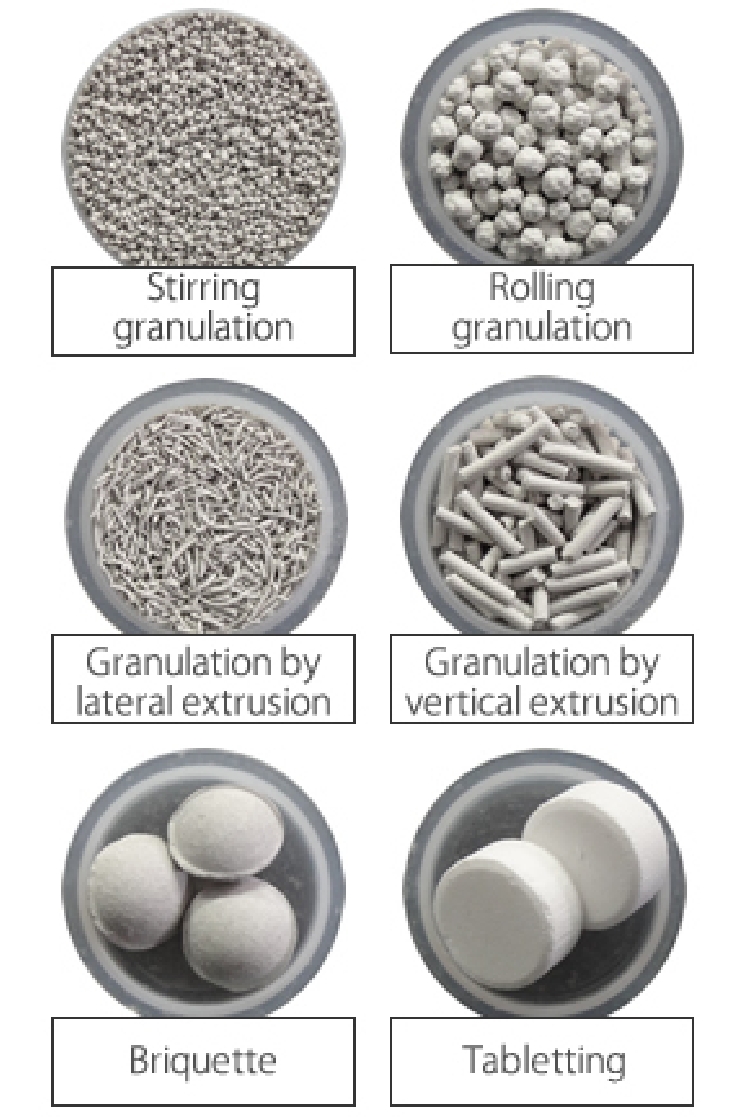

Granulation and ion exchange are described below as an example of addition of high value and an example of customization of our products, respectively:

Granulation

Just by making a powder product into granules, additional functions can be given to it.

- Reduce scattering of powder

- Improve ease of handling

Further functions can be added by mixing with other raw materials, adjusting adsorption or grain strength, or combining with a coating. - Adjust the hardness (ease of crumbling)

- Adjust the solubility and dispersibility

- Prevent elution

- Prevent color transfer

- Reduce odor

We select appropriate manufacturing methods and prepare formulation plans based on your requests.

Comparison of dispersion in toluene

Left:With no treatment / Right:Organically treated clay

Ion exchange

Montmorillonite, which is the main component of bentonite, has cation exchange and its properties can be changed by changing the cation types. In addition, exchanging with certain ion species, different properties can be given to it.

- Adjust dispersibility in water

- Adjust the viscosity of aqueous dispersion.

- Change adsorption ability

- Support ions

We have been engaged in research and development of ion exchange clay using ion exchange columns for many years and have a medium-scale pilot facility.

Organically treated clay that can be dispersed in organic solvents can also be prepared by ion exchange treatment. Organically treated clay is included in our lineup of products. However, if those products cannot be used, we develop and provide prototypes of organically treated clay.

If you have any inquiries about products, please contact us here:

If you want to add high value to existing products or make a scaled up prototype of a developed product, feel free to consult us.

Development flow

We carry out contracted development according to the following basic flow (it is not the case with short-term contracted manufacture):

Interview to determine details of development

study

Set a preliminary study period.

Submission of contracted development specifications

Submission of an estimate

Order receipt

Fabrication of a prototype

Submission of the prototype (delivery)

FAQ

The matter I want to consult you about contains confidential information ...

You do not need to disclose any details when making an inquiry. In the process of contracted development, the disclosure of detailed information is often required. Thus, confidentiality provisions are stipulated in the contract, but we will conclude a non-disclosure agreement with you if you desire to keep your information secret.